定制化服务,满足您的独特需求!河南正一机械,根据您的生产规模和要求,量身打造专属的AAC加气混凝土砌块生产线设备!

In today's world where green building and sustainable development concepts are increasingly becoming a global consensus, the annual production line of 100,000 m³ of Aerated Autoclaved Concrete (AAC) blocks, with its exceptional performance, high efficiency, and environmentally friendly production process, is leading a new round of transformation in the building materials industry. This article will provide you with an in-depth analysis of this production line, allowing you to appreciate the charm of green building materials and the immense potential of the future market.

I. Green Building Materials, Environmental Protection Takes Precedence

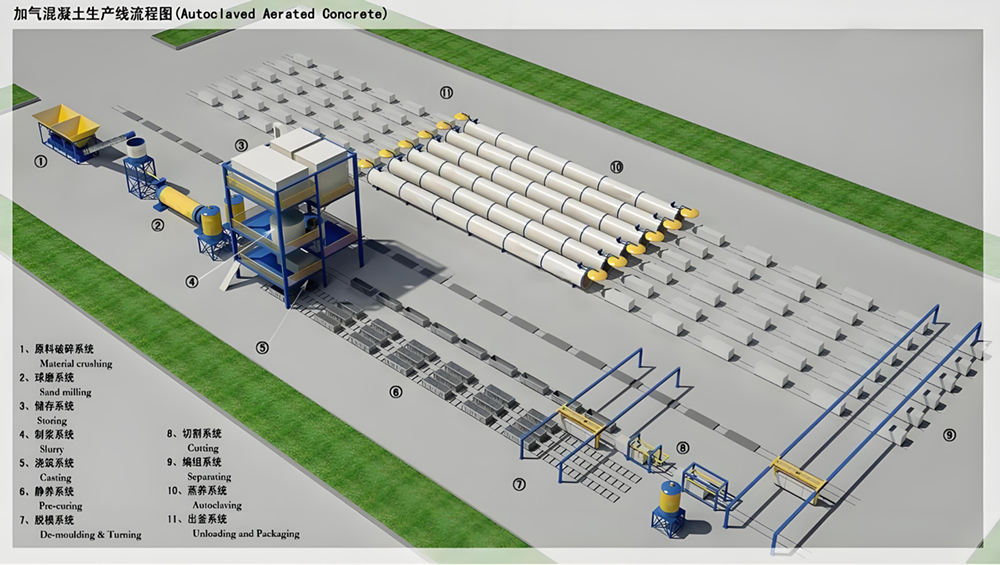

AAC blocks, as leading performers among new wall materials, have become the preferred material for green buildings due to their lightweight, thermal insulation, heat preservation, sound insulation, and earthquake resistance properties. The annual production line of 100,000 m³ utilizes advanced production processes to scientifically proportion siliceous materials (such as fly ash, sand) with calcareous materials (such as lime, cement), and through mixing, pouring, gas expansion, cutting, curing, and other processes, produces high-quality AAC blocks. The entire production process is environmentally friendly, complies with national energy conservation and emission reduction policies, and contributes to the green building industry.

II. Professional Team, Superb Skills

To ensure the stable operation and efficient output of the production line, we have equipped it with a professional operating team and maintenance engineers. The operators have undergone rigorous training, are familiar with the overall operation process of the production line, and can skillfully operate the equipment to ensure product quality. The maintenance engineers possess solid mechanical and electronic knowledge, enabling them to quickly locate and resolve equipment faults, ensuring continuous production on the production line. Additionally, quality control personnel and managers also fulfill their respective roles, jointly supporting the efficient operation of the production line.

III. High-Efficiency Production, Impressive Daily Output

The annual production line of 100,000 m³ boasts remarkable production efficiency. Under ideal conditions, the production line can produce 800~1100 m³ of AAC blocks per day, fully meeting market demand. This high efficiency is attributed to advanced production equipment and superb production processes. At the same time, the production line also has flexible capacity adjustment capabilities, allowing for flexible adjustment of production plans based on market changes to ensure long-term profitability.

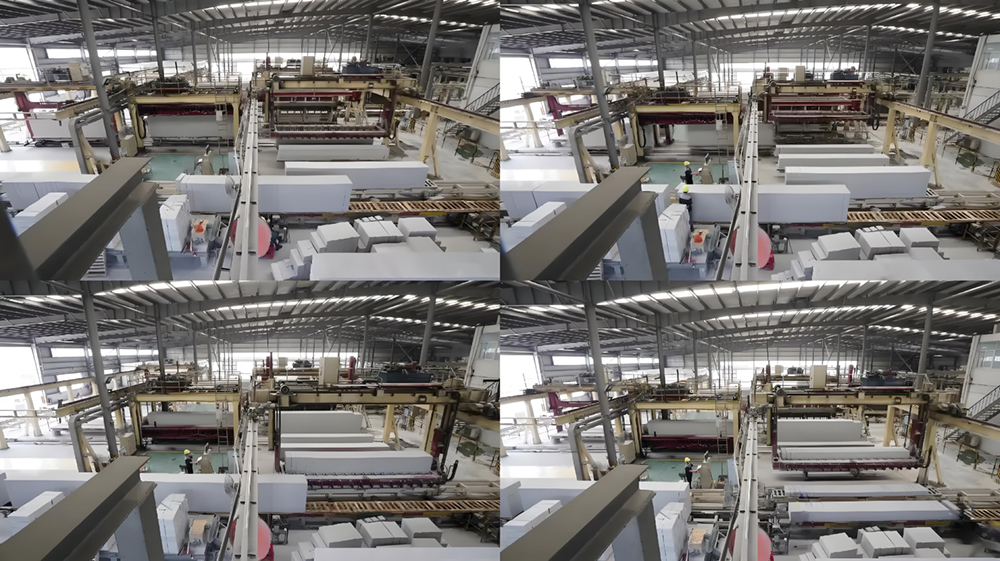

IV. Intelligent Management, Cost Reduction

The entire production line is equipped with an advanced automated control system, realizing intelligent operation from raw material proportioning, mixing and pouring, cutting and curing, to finished product dispatch. This not only significantly improves production efficiency but also significantly reduces labor costs. Additionally, the intelligent management system can monitor production data in real-time, providing strong support for production optimization, further reducing costs and improving economic benefits.

V. Broad Market Prospects, Considerable Earnings

With the continuous improvement of national building energy efficiency standards and the vigorous promotion of green buildings, the market demand for AAC blocks continues to climb. The annual production scale of 100,000 m³, combined with reasonable cost control and marketing strategies, can achieve annual earnings of tens of millions of yuan, with a short payback period and high return on investment. At the same time, the production line also has strong market competitiveness, able to provide customers with high-quality products and services, helping customers stand out in the fiercely competitive market.

VI. Professional Services, Full Support

We provide comprehensive services from production line design, installation and debugging, technical training to later maintenance, ensuring customers can operate without worry. The professional technical team will provide you with customized production solutions to help you build a green building materials production base that meets your needs. Additionally, we also provide continuous technical support and after-sales service to ensure the long-term stable operation of the production line.

Conclusion: The annual production line of 100,000 m³ of AAC blocks, with its high efficiency, environmental protection, and intelligent manufacturing characteristics, is becoming a rising star in the field of green buildings. Let us work together to promote the development of the green building industry and create a better future!

Through this soft article, we have not only comprehensively demonstrated the advantages and characteristics of the annual production line of 100,000 m³ of AAC blocks but also thoroughly analyzed its production process, market prospects, and economic benefits, aiming to attract the attention of potential customers and help enterprises explore broader market space.

Annual Production Line of 100,000 Cubic Meters of Aerated Concrete Blocks

This is an efficient and environmentally friendly production equipment specifically used for producing aerated concrete blocks. Here is a detailed introduction to this production line:

I. Overview of the Production Line

The annual production capacity of 100,000 cubic meters of aerated concrete blocks production line mainly utilizes siliceous materials (such as fly ash, sand, stone powder, etc.) and calcareous materials (such as lime, cement) for mixing, pouring, gas expansion, cutting, curing, and other processes to produce new building materials with thermal insulation properties. This production line has been produced and used in China for many years and has become a relatively mature new wall material production equipment due to its environmental protection and land-saving features.

II. Main Equipment and Parameters

Raw Material Processing Equipment

Lime crusher: Used for crushing lime.

Bucket elevator: Used to lift materials to a certain height for subsequent processing.

Jaw crusher: Used for crushing large pieces of raw material to meet production requirements.

Conveyor: Used for conveying raw materials, ingredients, and other materials in the production line.

Ingredient Metering Equipment

Slurry storage tank: Used for storing mixed slurry, generally equipped with a mixing device to prevent slurry settlement.

Electronic weighing scale: Used for accurately measuring various ingredients to ensure product quality.

Horizontal feeding conveyor: Conveys ingredients to the pouring mixer.

Pouring and Mixing Equipment

Diverting cylinder pouring mixer: Mixes the ingredients uniformly and pours them through the diverting cylinder to form block molds.

Cutting and Curing Equipment

Cutting machine: Composed of vertical cutting machines, horizontal cutting machines, cutting trolleys, etc., used for cutting the poured block molds into standard-sized blocks.

Autoclave curing equipment: Such as autoclaves, used for autoclave curing of the cut blocks to improve their strength.

Auxiliary Equipment

Molds, baseplates, autoclave cars, etc.: Used for block mold forming, curing, and transportation.

Waste slurry mixer, slurry pump, etc.: Used for processing waste materials and slurry during production to realize resource recycling.

III. Production Process Flow

Raw material preparation: Siliceous and calcareous materials are separately crushed, finely ground, and stored in raw material bins.

Ingredient metering: Various raw materials are proportioned and accurately measured according to a certain ratio.

Mixing: The metered materials are sent into the mixing mixer to form uniform slurry.

Pouring and molding: The mixed slurry is poured into the mold through the diverting cylinder to form block molds.

Cutting and curing: The poured block molds are cut into standard-sized blocks and undergo autoclave curing.

Finished product inspection and packaging: The cured blocks undergo quality inspection, and those passing are packaged and stored.

IV. Product Characteristics

Small capacity, light weight: The bulk density of aerated concrete blocks is generally 300-800 kg/m³, only 1/4-1/3 of solid clay bricks, significantly reducing the building's self-weight.

Excellent thermal insulation performance: The thermal conductivity of aerated concrete blocks is low, with insulation performance four times that of clay bricks and three times that of hollow blocks.

Good sound absorption and sound insulation effects: The porous structure gives aerated concrete blocks good sound absorption and sound insulation properties.

Excellent seismic performance: Due to their lightweight, the blocks greatly reduce the building's self-weight, improving seismic performance.

Various specifications and sizes: Aerated concrete blocks come in various specifications and sizes to meet various masonry needs.

V. Investment Benefit Analysis

Investing in an annual production line of 100,000 cubic meters of aerated concrete blocks has significant economic and social benefits. Raw materials are widely sourced, production costs are low, product market demand is high, and the production process is environmentally friendly and pollution-free. At the same time, the production line can be flexibly adjusted according to market demand to achieve large-scale production.

VI. Professional Talent and Production Efficiency Required for the Annual Production Line of 100,000 Cubic Meters of Aerated Concrete Blocks

Required Professional Talent

To ensure the normal operation and high-efficiency output of the annual production line of 100,000 cubic meters of aerated concrete blocks, the following professional talent is required for operation and maintenance:

Production line operators: These workers need to be familiar with the overall operation process of the production line, including raw material proportioning, mixing, pouring, cutting, curing, and other steps. They should have rich operational experience and good operational skills to ensure the stable operation of the production line and product quality.

Equipment maintenance engineers: Equipment maintenance engineers are responsible for the daily maintenance and troubleshooting of the production line. They need to have solid mechanical and electronic knowledge, enabling them to quickly locate and resolve equipment faults to ensure continuous production on the production line.

Quality control personnel: Quality control personnel are responsible for monitoring all aspects of the production process