定制化服务,满足您的独特需求!河南正一机械,根据您的生产规模和要求,量身打造专属的AAC加气混凝土砌块生产线设备!

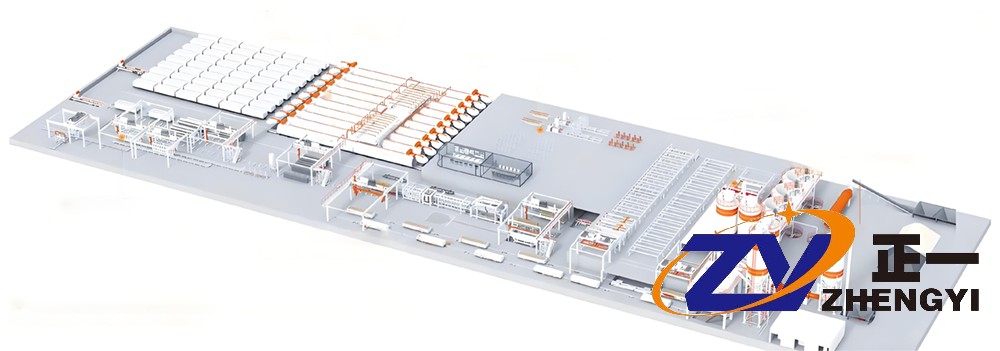

Introduction to the Annual Production Line of 50,000 m³ Aerated Concrete Blocks

I. Composition of the Production Line

The aerated concrete production line primarily consists of the following equipment:

Aerated Concrete Cutting Machine: It performs one-step, six-sided flipping and cutting of the green bodies, featuring advanced technology that eliminates the need for secondary lifting, thereby reducing damage to the green bodies.

Jaw Crusher: Used to process raw materials such as lump limestone into a certain powdered form. It is the primary equipment in the aerated concrete production line.

Ball Mill: Lumpy raw materials (such as limestone) that have been crushed are added into the ball mill to be processed to a certain fineness.

Mixing and Pouring Vehicle/Mixing and Pouring Machine: Used to pour the mixed slurry into the mold frame.

Vortex Slurry Preparation Machine: Used to prepare slurry, ensuring its uniformity and stability.

Autoclave Cart: Combined with the mold baseplate and mold frame, it is used to transport the cut green bodies into the autoclave for curing.

Lifting Devices and Molds: Lifting devices are used for mold stripping and lifting green bodies, while molds are used for shaping green bodies. Lifting devices are divided into automatic and manual types and can be used in a circular manner.

Autoclave: Used for high-temperature and high-pressure steam curing of green bodies to form porous and lightweight concrete products.

Boiler: Provides the high-temperature and high-pressure steam required by the autoclave.

Additionally, it may also include equipment such as bucket elevators, electromagnetic vibrating feeders, screw conveyors, slurry pumps, mobile mixing and pouring machines, double-hook synchronous cranes, gantry cranes, planetary winches, automatic hook lifting devices, manual lifting devices, and support rods.

II. Raw Materials and Formulas

The main raw materials for aerated concrete blocks include river sand, lime, cement, etc., with aluminum paste serving as the foaming agent and foam stabilizer. The specific formula is designed based on the type, quality, and process characteristics of the raw materials used by the customer.

III. Production Process

Raw Material Preparation: Crush and grind raw materials such as river sand, lime, and cement, and prepare foaming agents such as aluminum paste.

Batching and Mixing: Mix the prepared raw materials in a certain proportion and add an appropriate amount of water to form a uniform slurry.

Pouring and Foaming: Pour the mixed slurry into the mold frame, and through chemical reactions, gas is generated to make the slurry expand and form a porous structure.

Static Setting and Cutting: Allow the poured green bodies to set statically, and after they solidify, cut them into different specifications of blocks or boards.

Autoclave Curing: Transport the cut green bodies into the autoclave for high-temperature and high-pressure steam curing to increase their strength and meet usage requirements.

IV. Product Characteristics

Lightweight: Aerated concrete blocks are lightweight, facilitating easy construction and reducing the overall cost of buildings.

Excellent Thermal Insulation: Meets the national requirements for energy-saving construction of modern buildings.

Sound Insulation, Noise Reduction, Fire Resistance, and Water Impermeability: Possesses certain strength and processability, making it widely used in construction.

Eco-Friendly: As a new type of self-insulating wall material, aerated concrete blocks can replace solid clay bricks, meeting the building energy efficiency requirements proposed by the Ministry of Construction and promoting innovation in wall materials.

V. Market Prospects

With the continuous development of the construction industry in China and the country's increasing requirements for energy conservation and environmental protection, aerated concrete blocks, as an ideal wall material, have broad market development prospects. This production line can not only meet market demand but also bring good social and economic benefits.

VI. Suitable Investors and Regions

Suitable Investors: Investors with experience in the building materials industry, a deep understanding of the AAC block market, and sufficient capital and management capabilities.

Suitable Regions: AAC blocks are lightweight and have excellent thermal insulation properties, making them widely used in industrial and civil buildings. Therefore, they are suitable for investment in regions with high building energy efficiency requirements, such as cold northern regions, hot and humid southern regions, and economically developed regions.

VII. Annual Revenue and Payback Period

Annual Revenue: The revenue of an annual production of 50,000 m³ AAC blocks depends on factors such as market demand, sales prices, and production costs. Generally, the market demand for AAC blocks is large, and prices are relatively stable. Therefore, with reasonable control of production costs, the annual revenue can range from tens of millions to hundreds of millions of yuan.

Payback Period: The payback period is influenced by various factors, including total investment, annual revenue, and operating costs. Generally, if the total investment is around tens of millions of yuan, and the annual revenue is stable, the payback period may be around 3 to 5 years. However, please note that this is only a rough estimate, and the actual situation needs to be assessed based on specific projects.

VIII. Total Investment and Labor Costs

Total Investment: The total investment for an annual production of 50,000 m³ AAC block production line includes equipment purchase costs, civil engineering costs, installation and commissioning costs, working capital, etc. Based on market research and project experience, the total investment may range from tens of millions to hundreds of millions of yuan. The specific investment amount needs to be calculated in detail based on equipment selection, production scale, site conditions, and other factors.

Labor Costs: Labor costs include the wages and benefits of production line operators. Depending on regional differences and personnel skill levels, labor costs will vary. Generally, the wage level of production line operators ranges from thousands to tens of thousands of yuan per month. Additionally, the wages and benefits of management and technical personnel need to be considered.

IX. Daily Production Capacity of This Equipment

Regarding how many bricks an annual production line of 50,000 m³ aerated concrete blocks can produce in a day, it depends on various factors such as the production efficiency of the equipment, the operating condition of the production line, and the proficiency of workers. However, a rough estimate can be given based on general circumstances. Assuming the production line operates for 8 hours a day and the equipment is in good operating condition, the daily production capacity may range from hundreds to a thousand cubic meters of bricks, with the specific number needing to be calculated based on actual conditions.

It should be noted that the specific number of workers will vary depending on the scale of the production line, the degree of automation, and production demands. Therefore, in practical operations, reasonable arrangements should be made based on specific circumstances.

In summary, the annual production line of 50,000 m³ aerated concrete blocks is an efficient and eco-friendly building material production equipment with broad market application prospects. Investing in an annual production line of 50,000 m³ AAC blocks requires full consideration of factors such as market demand, production costs, investment scale, and payback period. Before making an investment decision, it is recommended to conduct detailed market research and project evaluations to ensure the feasibility and profitability of the project.